Cassina in Italy has been the manufacturer of the licensed reproduction Zig Zag chairs since 1973. They negotiated with the Rietveld estate and have become the exclusive manufacturer of the chair since then.

It's hard to put a price on fine Italian craftsmanship. Well maybe not that hard. In this case it's exactly $1704 USD (1270e). That's a lot of money. Don't get me wrong, I've seen the Zig Zag chair before, and it's absolutely beautiful, very precise build, and meticulous finishing. But $1704 is a LOT of money.

If you look around the Internet you'll see loads of reproduction Zig Zag chairs. They are almost all different in some aspect, either the back is 90 degrees instead of 98, or the proportions are all wacky, etc. It surprised me that nobody has a reproduction that is just like Cassina's. But then I suppose if it was too identical they would be sued for copyright infringement.

To me a big part of the fun is actually building a chair, and seeing if I can complete it, just as well as Cassina does. The other part is saving some money. Here is the breakdown:

Cassina: $1704 (plus tax and shipping)

My estimate:

Cherry wood, 8 ft, cut and jointed $125

Stain $10

Rubber feet for the base $5

Dowels $6

Glue $3

Top coat (Polyurethane, etc.) $10

So hopefully it will end up in the range of $160.

This of course, is just and estimate. I haven’t figured in the cost of hospital visits, surgery, bandages, etc.

The labor of course is where all the expense comes in. I estimate around 30 hours to put everything together. In reality it will probably come in around 6,870 hours. But that’s ok. I'll have fun doing it, and learning a few new things in the process.

Monday, November 25, 2013

Sunday, November 17, 2013

Picking some Cherry

I went to my wood source, Hardwood Resource, located in Martinez, Ca. Truxtun is very helpful when it comes to my many wood building questions. He also has lots of nice exotic hardwoods.

I picked out three pieces, all 8ft long (2.4m), and when I glue them together will be around 18" in width. These sizes give me enough room to work with, and a little scrap so I can test wood staining, etc., at the end.

Next step is to have the edges jointed.

Now that the edge jointing is done, it's time to have the wood planed to smooth the surfaces, and get a uniform thickness.

The planing went well, so now I have three pieces ready to be glued together.

I picked out three pieces, all 8ft long (2.4m), and when I glue them together will be around 18" in width. These sizes give me enough room to work with, and a little scrap so I can test wood staining, etc., at the end.

Next step is to have the edges jointed.

Now that the edge jointing is done, it's time to have the wood planed to smooth the surfaces, and get a uniform thickness.

The planing went well, so now I have three pieces ready to be glued together.

Saturday, November 9, 2013

Making a plan

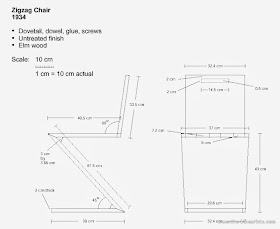

So I've found some information on the plans of the Zig Zag. There are a couple floating around the internet, but I've decided on one. There are LOADS of Zig Zag chairs that people have reproduced, and very few of them seem to be identical. Most have a 90 degree seat back (easier to build), or they are slightly taller, or wider than the original.

Since Cassina has been making the Zig Zag since the early 70's, I figured their design would be the most accurate. When you look at other Zig Zag reproductions, nothing looks quite as right as the Cassina. Since I live in the San Francisco area, I have the ability to actually go and see one of these at the Cassina retailer here. It helps a lot to actually get a hands on look at the design before building one!

Since Cassina has been making the Zig Zag since the early 70's, I figured their design would be the most accurate. When you look at other Zig Zag reproductions, nothing looks quite as right as the Cassina. Since I live in the San Francisco area, I have the ability to actually go and see one of these at the Cassina retailer here. It helps a lot to actually get a hands on look at the design before building one!

Monday, November 4, 2013

Back to the beginning

When I was in college 25 years ago I studied design as part of my Photography degree. We were taught about Bauhaus, DADA, and De Stijl (The Style) movements amongst others. When it came to De Stijl, we went over works by Mondrian, Doesburg, and Rietveld.

The first time I saw Rietvelds’ Zig Zag Chair I thought it was amazing. It had such sleek lines, and was so minimal, yet functional, and whenever I saw it again I was fascinated by it. I would occasionally see it at design stores, or a museum shop, but at that time I had very little money, and no possible way to acquire one. The official versions were produced by Cassina in Italy, and if I remember correctly the price was around $1000 US – (728 EU), in the late 1980’s, which was way out of my price range then.

While in high school and college, I worked a lot in the wood shops. I found that I could be very creative and build all kinds of fun designs. After college I took some woodworking classes, and had access to more tools. I thought for just a moment about the Zig Zag chair. At that time I had NO idea of how it was built, or how I’d even start to make one. The design of it presented too many challenges to me:

•The handle in the back is routed. I didn’t know how to do that then.

•The dovetail joint in the seat was new to me; I’d seen them before but had no experience with them, or the equipment needed to make that joint.

• The other two angles used, on the seat and base, are very severe. How to safely cut those angles was beyond me.

•The seat and back don’t come together at 90 degrees (it’s at 98). Again, I had no idea how to make that assembly.

•The seat was capable of holding a lot of weight, but how? It seemed to just have those wedge pieces in place.

• The chair elements are not straight lines; each piece tapers, and comes together at odd angles.

Well that was enough for me. There was no way I could figure this design out back then.

After that I began to look at Rietvelds’ Red/Blue chair. It looked comfortable, it had relatively easy looking joints (just simple dowels needed), and no crazy angles! I was able to get the original plans for it, and I was on my way.

It went together pretty well, and turned out nice. I wasn’t a fan of all that color, so the one I built was made using solid maple, and marine grade plywood for the seat and back. I still have it in my home today.

Over two decades passed, and I decided to continue with my Rietveld chair production. I really started to appreciate the Steltman chair, and as you can see here I started this blog to document the building of it. It came out great, and I was once again happy.

But…. In the back of my mind the Zig Zag was always there, the first design of his that I really liked. In the years that passed between building the Red/Blue, and Steltman I was able to build my workshop (my garage) and get some new tools. At this point I had a table saw, drill press, disc sander, router table and lift, and my wood skills had become much better.

Then as I surfed the net during this last summer, I came across this intriguing video on YouTube:

Wow, there it was, the chair being built by the masters, and I could actually see how much of it was done!

I must have watched the video a dozen times, and many more times since, trying to catch a glimpse of every little detail. It was at that time that I decided to build one. I was confident in my abilities, and I knew I had the tools needed to finish it.

Now I’m starting one! If all goes well, I’ll have a working reproduction of one in the near future. I will take as many pictures as I can along the way. If you have any questions or comments please e-mail me:

Eastbayboy99(at)hotmail(dot)com

Thanks